500 Stokes high speed punching press

Metal lath machine

- Metal lath and Brickwork mesh machine

- Self Furred Metal lath production line

- Brick reinforcement production line

- High speed angle bead production line

- Angle bead production line

- Plaster stop production line

- High speed Rib lath production line

- Rib lath production line

- High speed Hi-rib lath production line

- Hi-rib lath production line

- Architrave bead machine

- Movement bead production line

- Corner bead production line

- Vinyl bead production line

Metal lath

- Rib lath

- Diamond metal lath

- Hi-rib lath

- Brickwork reinforcement

- Self-furring metal lath

- Paper back metal lath

- Spray lath (v-groove)

- Stainless steel lath

Expanded Metal bead

| Home Page | Metal Lath machine | Metal Lath | Technical FAQ | Application | Video | Quotation | Contact Us |

You are here: Mesh making machine → Rib lath production line

Parameter:

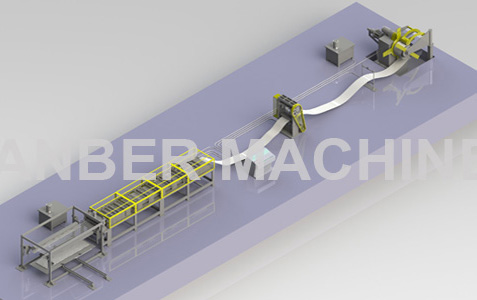

Layout: feeding trolley - uncoiler - expanded main machine - roll profiling machine - hydraulic rib lath shearing machine - hydraulic automatic rib lath collect - control cabinet

Material to produce rib lath: 0.3-0.6mm thickness and 420mm width galvanized sheet

Rib lath parameter:

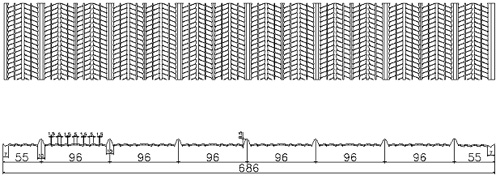

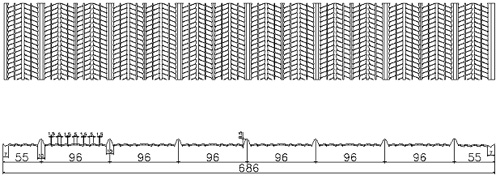

Length: 2493mm, width: 686mm

Dimensions: strand width 1.5mm, plate thickness: 0.3-0.6mm, rib distance 98mm, LWD: 10mm, SWD: 5mm

ID of the material: 510mm-608mm

OD of the material: Max. 1900mm

Loading weight: Max. 5000Kg

Feeding width: 350-450mm

Total Motor power : 19.5KW

Reducer: BWED53

Capacity of hydraulic station: 0.36cbm

Hydraulic oil: 40#

Expanding speed: Max. 200 strokes/min

Mold driven: Belt

Mold strokes: 16.5-23mm, material: Cr12MOV, hardness: HRC50

Mold Travel: 16.5-23mm

Forming roller QTY: 18, diameter: 110mm, material: 45# steel, hardness: HRC34-48

Straightening roller QTY: 9 pcs, diameter: 100mm, material: 45# steel, hardness: HRC34-48

Cutting speed: 5s/stroke

Mold Material: GCr12

Capacity of hydraulic station: 0.1cbm

Hydraulic oil: 40#

Rotate angle of the support bord: 90 degree

Hydraulic cylinder travel: 200mm

Dia. of hydraulic cylinder: 40mm

Oil capacity of hydraulic station: 0.1cbm

Hydraulic oil: 40#

Overall size of rib lath machine: 25000กม5000กม3000mm

Electrical controlling cabinet:

PLC: Panasonic IPO-AROMAT

Electric elements: Schneider

Finished Products:

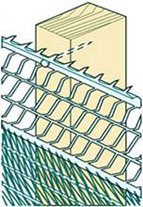

Rib- lath is expanded metal-lath stiffened with longitudinal ribs. The furring design of the mesh provides efficient background plaster for construction of partition, suspended ceilings and refurbishment works. The advantage of ribbed- lath over metal-lathing is that support centers can be increased or widened.

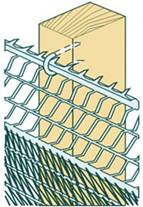

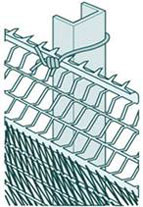

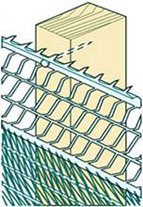

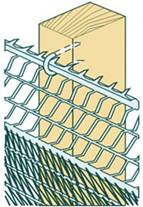

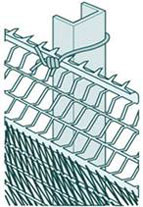

Rib lath is ideal for refurbishing damaged or aged masonry walls, when a key for rendering is not certain due to disintegration or softening of the wall face. Lath should be fixed with apexes of ribs against the wall, edge ribs of sheets should be lapped not less than 2.5cm and nesting ribs securely tied together. Stainless steel fixings should be used at sufficient intervals to hold the lath firmly in position.

Application:

Rib lath is idea for refurbishing damaged or aged masonry walls, when a key for rendering is not certain due to disintegration or softening of the wall face. Lath should be fixed with apexes of ribs against the wall, edge ribs of sheets nesting into each other should be wire-tied every 15cm and ends of sheets should be lapped not less than 2.5cm and nesting ribs securely tied together. Stainless steel fixing should be used at sufficient intervals to hold the lath firmly in position.

Install Rib Lath with U staple Install rib lath with rope Install rib Lath with nail

Rib lath production line

Description:

The rib lath machine is used to produce the rib lath which is applied to plaster the concrete and reinforce the wall light weight and high reinforcement

rib lath machine effect map

rib lath machine

rib lath making machine

rib lath production line

rib lath machine controller

Parameter:

Layout: feeding trolley - uncoiler - expanded main machine - roll profiling machine - hydraulic rib lath shearing machine - hydraulic automatic rib lath collect - control cabinet

Material to produce rib lath: 0.3-0.6mm thickness and 420mm width galvanized sheet

Rib lath parameter:

Length: 2493mm, width: 686mm

Dimensions: strand width 1.5mm, plate thickness: 0.3-0.6mm, rib distance 98mm, LWD: 10mm, SWD: 5mm

ID of the material: 510mm-608mm

OD of the material: Max. 1900mm

Loading weight: Max. 5000Kg

Feeding width: 350-450mm

Total Motor power : 19.5KW

Reducer: BWED53

Capacity of hydraulic station: 0.36cbm

Hydraulic oil: 40#

Expanding speed: Max. 200 strokes/min

Mold driven: Belt

Mold strokes: 16.5-23mm, material: Cr12MOV, hardness: HRC50

Mold Travel: 16.5-23mm

Forming roller QTY: 18, diameter: 110mm, material: 45# steel, hardness: HRC34-48

Straightening roller QTY: 9 pcs, diameter: 100mm, material: 45# steel, hardness: HRC34-48

Cutting speed: 5s/stroke

Mold Material: GCr12

Capacity of hydraulic station: 0.1cbm

Hydraulic oil: 40#

Rotate angle of the support bord: 90 degree

Hydraulic cylinder travel: 200mm

Dia. of hydraulic cylinder: 40mm

Oil capacity of hydraulic station: 0.1cbm

Hydraulic oil: 40#

Overall size of rib lath machine: 25000กม5000กม3000mm

Electrical controlling cabinet:

PLC: Panasonic IPO-AROMAT

Electric elements: Schneider

Finished Products:

Rib- lath is expanded metal-lath stiffened with longitudinal ribs. The furring design of the mesh provides efficient background plaster for construction of partition, suspended ceilings and refurbishment works. The advantage of ribbed- lath over metal-lathing is that support centers can be increased or widened.

Rib lath is ideal for refurbishing damaged or aged masonry walls, when a key for rendering is not certain due to disintegration or softening of the wall face. Lath should be fixed with apexes of ribs against the wall, edge ribs of sheets should be lapped not less than 2.5cm and nesting ribs securely tied together. Stainless steel fixings should be used at sufficient intervals to hold the lath firmly in position.

Model |

Name |

Sheet size |

Wt (lbs) |

Wt (kg) |

PCS/BDL |

PCS/PLT |

RB2.75 |

1/8"rib-lath |

27"กม96" |

3.7 |

1.7 |

10 |

500 |

RB3.4-1 |

1/8"rib-lath |

27"กม96" |

4.4 |

2 |

10 |

500 |

RB3.4-3 |

3/8"rib-lath |

27"กม96" |

5.1 |

2.3 |

10 |

500 |

RB4.0 |

3/8"rib-lath |

27"กม96" |

5.7 |

2.6 |

10 |

500 |

Rib lath is idea for refurbishing damaged or aged masonry walls, when a key for rendering is not certain due to disintegration or softening of the wall face. Lath should be fixed with apexes of ribs against the wall, edge ribs of sheets nesting into each other should be wire-tied every 15cm and ends of sheets should be lapped not less than 2.5cm and nesting ribs securely tied together. Stainless steel fixing should be used at sufficient intervals to hold the lath firmly in position.

Install Rib Lath with U staple Install rib lath with rope Install rib Lath with nail

Copyright© 2008-2019 Wuxi Anber Machine

All Rights Reserved.

Tel: 0086-510-88239309/88239310; Fax: 0086-510-88237950; QQ: 2355379753/2355379757

Email: sales@anber-inc.com ; kathy@anber-inc.com

Tel: 0086-510-88239309/88239310; Fax: 0086-510-88237950; QQ: 2355379753/2355379757

Email: sales@anber-inc.com ; kathy@anber-inc.com